Book your Order before

31st March

and Get 2 Years AM

at 50% Discount.

Enquiry Form

7 Facts that you Must Know before Buying a Transformer.

Over 53% Buyers Ignore the Selection of Appropriate Specifications and loose up to Paying

23% on Investment and Running Cost.

Voltage Ratios

Accurate Voltage selection on H.V. Side – 11 KV, 22 KV, 33 KV and on L.V. Side – 400 V, 415 V or 433 V can vary the Cost of Transformer from 3% to 17%.

Capacity

Choosing the right KVA Rating of a Transformer based on Power Consumption in KW or Current & Voltage can lead an XFMRs Price variation from 8% to 13%.

Frequency

In most parts of the World, the Frequency of Power Supply is 50 Hz. but in Countries like USA the Standard Frequency is 60 Hz. This alter the design of Power & Distribution Transformer and effects the cost up to 5%.

Installation / Environment

Based on the type of atmosphere the Transformer will be placed in – Indoors, Outdoors, Salinity, Heat, Moisture, Fumes etc. goes into the Mechanical Designing and Paint Coating of XFMR. Contributing up to 7%.

Tappings

Taps on H.V. with Off Circuit Tap Changer or On Load Tap Changer, plays a significant role in the Electrical Designing and Cost Consideration of a XFMR and can vary up to 11% depending on Transformer Rating.

Standards

Many National and International Regulations are set to abide before buying a Transformer. Standards put up by Organizations like EEE, IEC, IS, BIS, IEEE, ANSI, NEMA, ASTM, UL are mandatory to follow. These standards goes into the Electrical Design consideration of XFMR and varies it up to 37%.

Fitting / Accessories & Protection Level

Several Electro-Mechanical Devices can be integrated with a Transformer for its safe functioning and appropriate monitoring. Especially for XFMRs of High Ratings, these Fittings and Protections are must for Enclosure Safety, Alarm & Trip functions for Temperature and Pressure Control. Depending of the KVA Capacity of XFMR, these contribute up to 17%.

About Recons

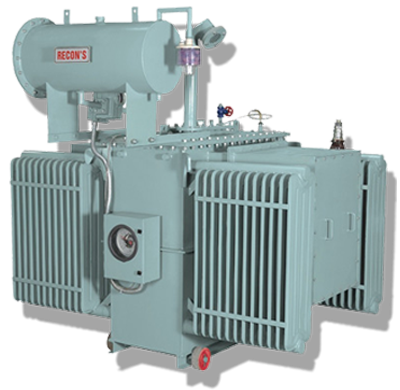

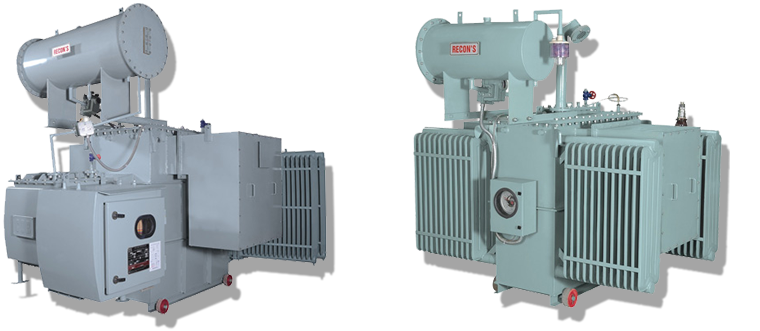

RECONS covers a wide range of Oil Filled Distribution Transformers with On Load Tap Changer (up to 5000 KVA in 11 KV & 33 KV Class) conforming to the international standards of quality and safety. These transformers are designed and developed using latest technologies and can be provided with a variety of terminations so as to suit the requirements for new installation or replacement.

Optimum efficiency is ensured by delicate proportioning of core and winding looses using CRGO M3 to M5 MOH Lamination, Electrolytic Grade 99.9% pure copper, with Transposition in L.V. coil for current sharing in parallel Conductors, Electric grade press paper, boards and mineral oil. Thus better regulation is achieved resulting in longer life. Careful designing also reduces noise level to the minimum.

Power & Distribution Transformer

Oil Cooled Power Transformer & Oil Cooled Distribution Transformer available upto 5000 KVA in 11 & 33 KV Class.

Standard Specification

Capacity – Up to 5000 KVA

No. of Phases – 3 Phase

Frequency – 50 Hz.

Voltage Range – 11 KV / 22 KV / 33 KV

Tapping – +5% to -15% Taps on H.T. Side in steps of 1.25% each.

Insulation – Class ‘A’

Vector Group – Dyn 11

Duty Cycle – Continuous

Winding – Copper Wound

Terminals – As per required

Standard Fittings

Rating & Diagram plate – Earthing terminals

Lifting lugs – Thermometer pocket

Oil Conservator with drain plug – Air release hole with plug

Oil Level indicator – Explosion vent with diaphragm

Top-filter Valve – Inspection cover.

Silica gel breather – Drain –cum-bottom-filter valve

Cooling radiators – Uni / Bi- directional rollers